Strip nails are a type of steel nails that are made from circular wire (high, medium, or low carbon steel) as raw materials. They are pulled (cold drawn) several times by a wire drawing machine to the required wire diameter for steel row punching. The nails are produced by a nail making machine, quenched in a heat treatment furnace, polished by a polishing machine, electroplated by a galvanizing equipment, and finally glued manually to form rows of steel nails.

Strip nails are produced using a series of production processes that effectively integrate individual nails arranged in a regular manner. They are integrated with special adhesive to form a fixed and regular row with a carbon content of 0.4-2.8%, which is higher in hardness than steel nails. Due to their high strength and hardness, they can be nailed into relatively hard materials such as concrete, making them widely used in indoor decoration, wooden packaging boxes, and other fields.

What are the characteristics of Strip nails?

1. The row of steel nails must be 40 in a row, and the top and sides must be flat and not warped

2. Steel row nails must have a certain degree of rigidity and strength: hold one end, and the other end must not sink or break.

3. The nails must be in close contact with each other without any gaps. The adhesive should be evenly applied without any lumps or bubbles, and the adhesive boundary should be limited to 10mm below the nail head

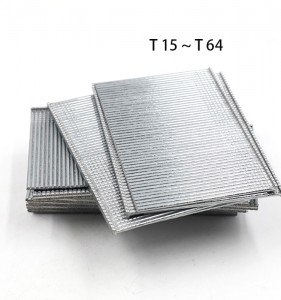

Size and model of steel row nails:

The Strip nails are composed of multiple steel nails arranged in a row. The diameter of a single steel nail is 2.2mm, and the lengths are: 18mm, 2mm, 38mm, 46mm, 50mm, 64mm, and other sizes.

There are eight main models of steel bar printing, namely ST-18, ST-25, ST-32, ST-38, ST-45, ST-50, ST-57, and ST-64, among which ST-25 and ST-32 are more commonly used.

We are committed to providing high-quality fasteners. If you would like to know more, please contact us.

Post time: Jul-10-2023